Large Component Structural Fabrication Services

(Click Each Image to Enlarge)

Westfield Machine, Inc. has been servicing customers in the oilfield and gas turbine industry for over 30 years-providing personalized customer service with a hands-on approach to custom fabrication. We are a family owned operation that delivers turnkey solutions and builds large scale structural components for customers across Texas and the Gulf region.

Westfield Machine, Inc. utilizes various fabrication methods including: brazing and welding from AWS certified welders, forming (bending, punching, shearing, and notching), as well as CNC machining. For prototypes through large scale productions, materials spanning structural, carbon, stainless steel, cast iron, Hastelloy, and Inconel, as well as in raw form which include sheet, tube, plate, H, and I-beam, and C-channel. Fabrication can be performed on raw materials up to .5" in thickness, 10' in length, 5' in width and height, and up to 15 tons. On-site assembly is performed by qualified ironworkers, with typical turnovers of 4 to 6 weeks as well as rush service. Finishing services such as powder coating, painting, and galvanizing is also available-making Westfield Machine, Inc. a true single source solution for all of your structural fabrication projects.

To learn more about what Westfield Machine, Inc. can do for you see the table below or contact us directly.

Request InfoLarge Component Structural Fabrication Project Showcase

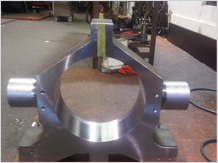

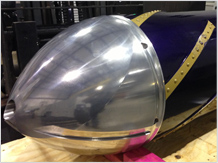

- Custom Aluminum Spir-o-lizer for the Oilfield Industry

- Custom Stabbing Guides & Body Components for the Oilfield Industry

- Custom Drive Gear Sets for the Construction Industry

- Custom Hydraulic Parts for the Oilfield Industry

Large Component Structural Fabrication Capabilities

- General Capabilities

- Structural

Large Components

Heavy Components

- Fabrication Method

-

- Welding (Wire, Heliarc®, Stick)

Brazing

Shearing

Bending

Ironworker - Punching

Notching

Sawing

CNC Machining Services

- Welding (Wire, Heliarc®, Stick)

- Materials

-

- Carbon Steel

Stainless Steel

Aluminum

Cast Iron - Hastelloy®

Inconel®

Structural Steel

- Carbon Steel

- Raw Material Forms

-

- Sheet

Tubing

Plate

Angle - H-Beam

I-Beam

C-Channel

- Sheet

- Material Thickness

- Up to 1/2 in.

- Punching Thickness

- Up to 3/8 in.

- Hole Diameter

- Up to 1 in.

- Length

- Up to 10 ft.

- Width

- Up to 5 ft.

- Height

- Up to 5 ft.

- Weight

- Up to 15 tons

- Tolerance (+/-)

- .125 in.

- Fabricated Products

-

- Toolboxes

Crates

Skids

Fixturing

Carriers - Safety Products

Truck Beds

3 Part Tanks

Storage Box

Pump Skids

- Toolboxes

- Additional Services Provided

- Powder Coated

Painted

Galvanized

- Production Volume

- Prototype to Large Scale Production Volume Runs

- Typical Lead Times

- 2 to 4 weeks

Rush Service Available

Additional Information

- Industries Served

- Oilfield

Gas Turbine

- Intended Applications

-

- Draw Work Parts for Oil Rigs

Blow Out Preventer (BOP)

Risers

Flow Crosses

Recalibration on Fixturing - Inspection Fixtures

Flanges

Double Lead Threading

Subseat Bonnets

Pipe Handling

- Draw Work Parts for Oil Rigs

- Industry Standards Met

-

- API Spec Q1

API ISO 9001:2015

- Mil-Spec

ASTM

AWS

- API Spec Q1

- File Formats Accepted

-

- SolidWorks

AutoCAD - GibbsCAM

Shop Talk

- SolidWorks

Print This Page

Print This Page